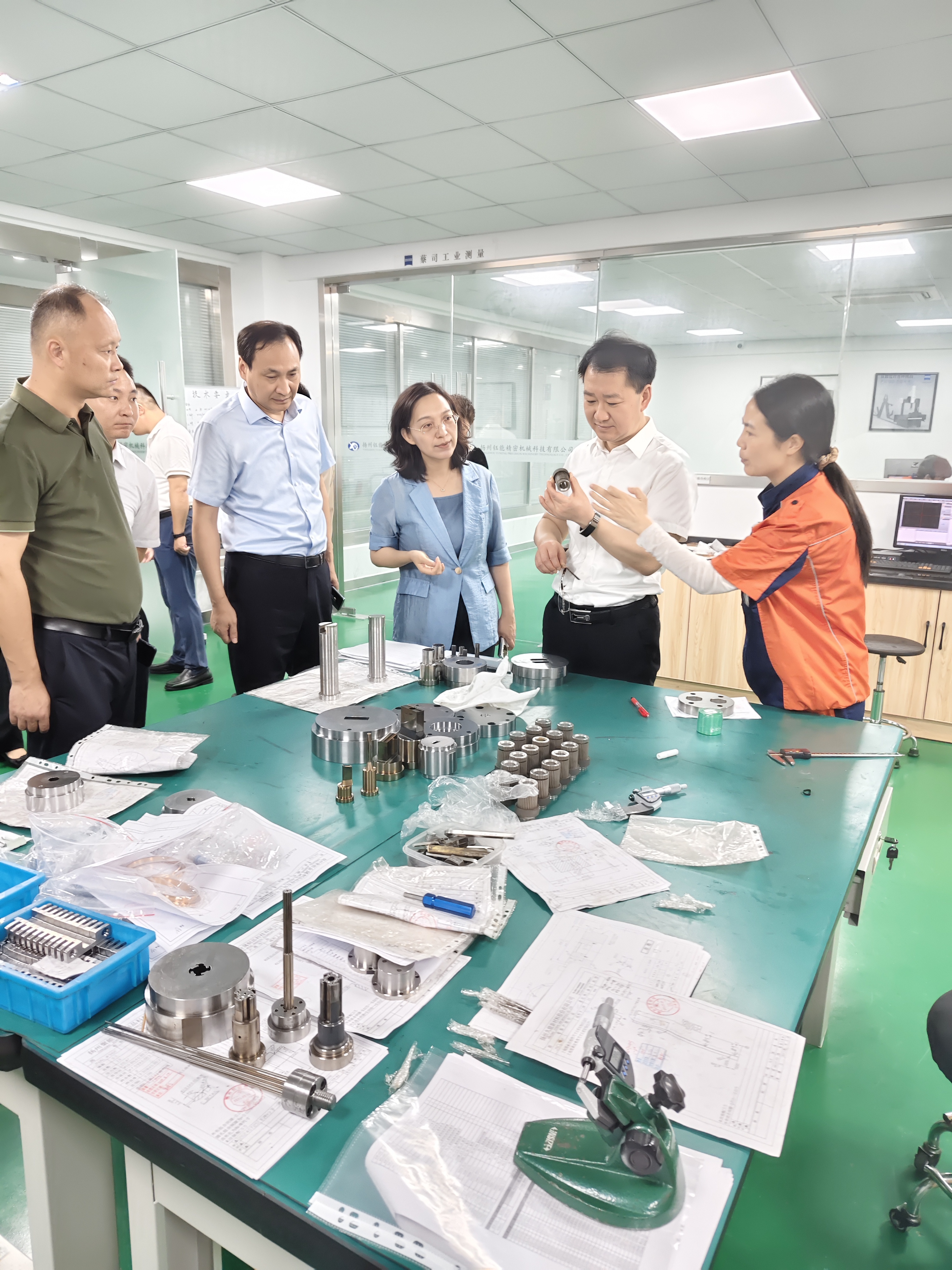

ABOUT US

Yangzhou Yuneng Precision Machinery Technology Co., Ltd. has sharpened its sword for ten years. Since its establishment in 2013, We have assembled a team of seasoned professionals with deep technical expertise in the design and manufacturing of reducers, precision molds, and high-accuracy components.The company has become a well-known powder metallurgy mold enterprise in the industry, with dry powder pressing mold as a breakthrough, focusing on technical advantages, expanding a larger market, and widely serving molds and precision machinery components in the aviation industry, new energy, rail transit and other fields!

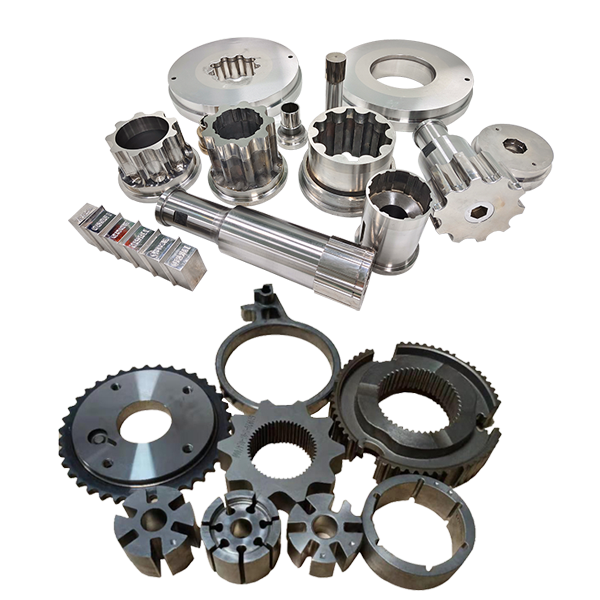

Automotive Parts and Electric Tools

1The application scope of automotive components covers various core systems of automobile manufacturing, primarily used in the engine system, transmission, drive system, braking system, etc. of automobiles.

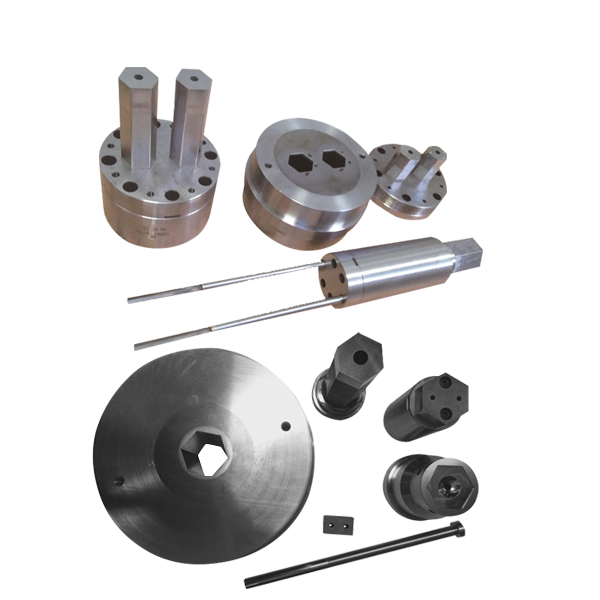

Aviation industry

2The application fields of the aviation industry are mainly divided into two categories: military and civilian, covering multiple aspects such as national defense and security, emergency rescue, transportation, and low altitude economy.

New energy

3The application scope of new energy covers multiple fields, mainly including green transportation, green buildings, green agriculture, and green manufacturing. Applications in fields such as new energy electric vehicles and fuel cell vehicles.

Rail Transit

4Rail transit is mainly used in urban public transportation systems, covering various standards such as high-speed rail, subway, light rail, and tram. It has the characteristics of large capacity and fast speed, which can alleviate urban traffic congestion problems.

Power

5Electricity is mainly used in industrial production, energy conversion and distribution, information technology in communication, transportation and other fields.

2025-07-05

The development strategy of powder metallurgy automotive parts in our country.

The composition of the cost of powder metallurgy parts.

CONTACT US

Address: No. 48, Xiganquan East Road, Yangzhou City, Jiangsu Province, 20-21, Hanjiang Zhizao Valley, Yachuang High Tech

Telephone:0514-87455899 to 8803

E-mail:yw@yzynjj.cn

Focus on us

View mobile terminal

Quick Navigation

Address: No. 48, Xiganquan East Road, Yangzhou City, Jiangsu Province, 20-21, Hanjiang Zhizao Valley, Yachuang High Tech

Telephone:0514-87455899 to 8803

E-mail:yw@yzynjj.cn

Copyright © 2025 Yangzhou Yuneng Precision Machinery Technology Co., Ltd.

Screen Flip Component Settings Panel

容器ID名称:#c_grid-1646471334705

关闭翻屏分辨率:768